The History Of The 3D Printer

05 May, 20203:13The market for 3D printers has exploded in recent years as advances in technology and reduct...

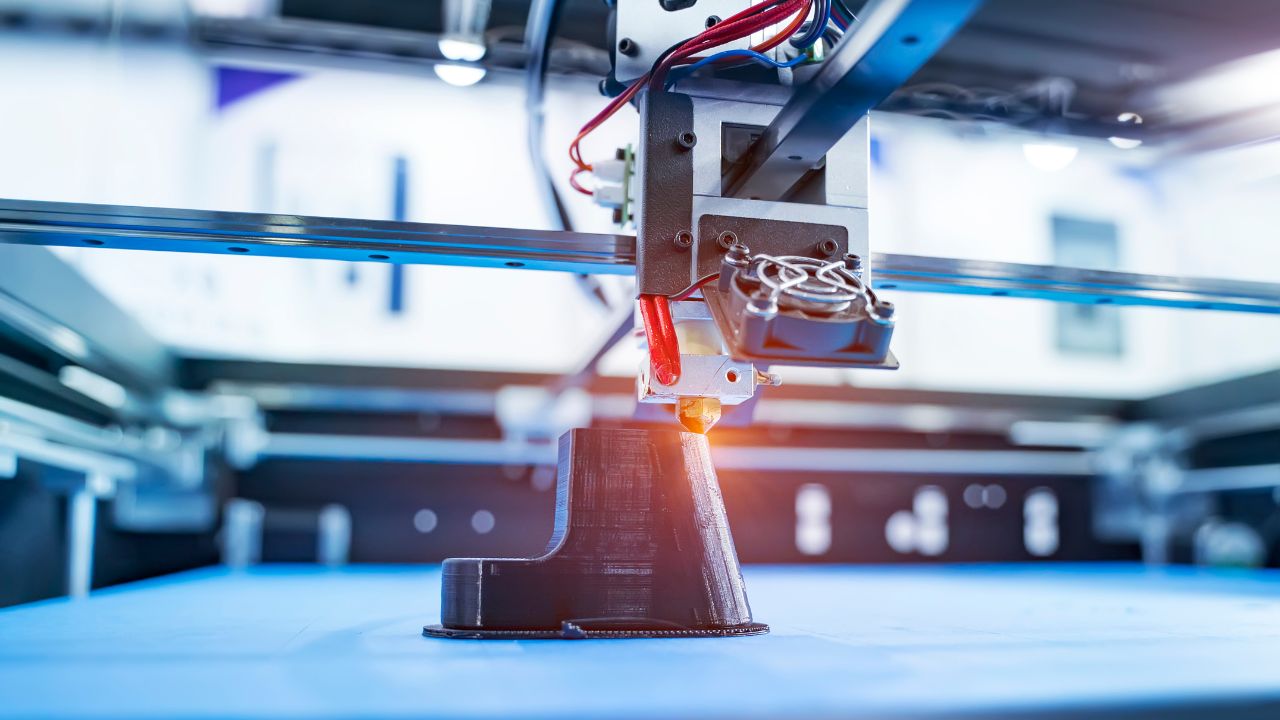

The market for 3D printers has exploded in recent years as advances in technology and reduction in prices means that both consumer and commercial machines are now commonplace. From design models to machine parts and - particularly in recent times - medical equipment able to be printed at scale, round the clock, in precise detail, the benefits of 3D printing technology is huge.

But is the technology really as new as it seems?

In fact the first commercial 3D printer was released by the 3D Systems Corporation - a company founded by engineer Charles “Chuck” Hull who had patented his system two years previously and coined the term “stereolithography”.

In fact the idea had been around for over a decade before it would become a reality, with British scientist and writer David E. H. Jones outlining the concept in an article for New Scientist.

By 1984 there were in fact 3 major patents for what would later be known as 3D printing. The first was filed by American entrepreneur Bill Masters for his Computer Automated Manufacturing Process and System. It is considered the foundation for today’s 3D printers.

The second belonged to French inventors Alain Le Méhauté, Olivier de Witte, and Jean Claude André, but despite the workable system the three scientists lacked the business perspective to grow it.

Chuck Hull’s “stereolithography fabrication system” was patented in August 1984, with a process involving curing layers of photopolymers with ultraviolet light lasers. As the light hit the liquid photopolymer - an acrylic based material - it would instantly turn solid. Hull’s patent was granted in 1986 and his company released the SLA-1.

Though methods and materials would change over the years, the basic principle would remain the same. The SLA-1 would craft objects by solidifying slices of material layer by layer from a slowly submerging build tray. Each layer would have a thickness of 0.05 to 0.15mm, depending on laser strength, material or tolerance desired.

An important aspect would be the computer design that could break down the cross section of a proposed model into the desired slices. 3D Systems developed the STL file format (an abbreviation of stereolithography) that would allow users to map the surface geometry of a three-dimensional object using layers of connected triangles. The STL file format is still widely used in 3D printing, rapid prototyping and computer-aided manufacturing.

The benefits of 3D printing’s use as an automated manufacturing process was clear from the start, but the systems were not without their problems. The process was a slow one, taking several hours to craft even the smallest and most basic shapes. Initially there were issues with the material warping as it hardened. But most importantly it was extremely expensive.

Though this prohibited most private uses of 3D printing, research and development went on and through the ‘90s, many new usages were found both in automated manufacture and in medical technology. In 1999 the first ever 3D printed organ was implanted in a human - a synthetic human bladder made with scaffolds printed by scientists at Wake Forest Institute for Regenerative Medicine and coated with cells of human patients. Because cells came from the patient themselves, the artificial organ was less likely to be rejected by the body than person-to-person transplant.

Over the following 10 years, medical 3D printing would create a functional miniature kidney, a complex prosthetic leg and bioprinted blood vessels using only human cells.

By 2006 SLS machines were finally commercially viable - with smaller sizes, different print materials and lower costs meaning that industrial parts of all sorts could now be developed.

These days 3D printing is used throughout the manufacturing and design world. In recent weeks this technology has been in the headlines a lot as manufacturers quickly switch their normal processes to develop thousands of parts for ventilators, PPE and other medical supplies. Crafting new parts at scale quickly, accurately and efficiently is a major benefit that comes from this sort of automated printing and will no doubt set a precedent for future growth in the technology.

50 Years of Engineering

1986 marks the release of the world’s first 3D printer - a milestone in engineering that has changed the world. Each week we’re celebrating similarly groundbreaking engineering accomplishments made between the years 1970-2020, to celebrate Fircroft’s 50th anniversary.